07 Dec The evolution of bromine flame retardants towards brominated polymers

COMBINING PERFORMANCE AND EFFICIENCY, WHILE ENSURING A GOOD ENVIRONMENTAL PROFILE

Our modern lifestyle has some clear requirements. Living, working, travelling? Everything happens in a practical, comfortable and energy efficient manner. Plastics, composites, foams, synthetic fibre-based fillings and other highly flammable materials are necessary to meet our daily needs. But these materials unfortunately come with an increased risk of fire. Luckily, there is a way to avoid or to slow down the burning process. Brominated flame retardants make sure that safety can be added to the checklist of our contemporary lifestyle.

The cost of comfort

We all use electronic equipment, upholstered furniture, carpets, wall coverings and drapery, airplanes, cars and other modern transportation, building and insulation materials. All these materials, as well as oil-based plastics and synthetics are highly flammable materials which are constantly present in your daily life.

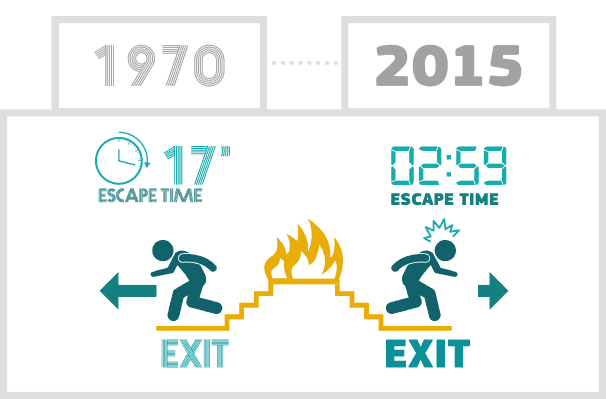

This shift to more flammable materials used in in our daily lives and homes has drastically shortened the escape time from burning spaces – from 17 minutes in 1970 to around 3 minutes in 2015. Because of this, flame retardants in materials play a vital part meeting fire safety standards designed to increase escape times. They significantly delay the ignition in the early stages of a fire, which makes them extend escape time.

Fire protection for all materials & degrees of safety

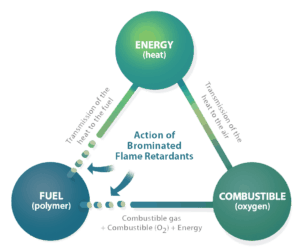

In case of a fire, temperature rises and flammable gasses fill the room. This results in a rapid spread of flames, and – after some time – makes all inflammable materials reach their ignition point.

A flame retardant is a substance that slows down this chemical reaction, making flammable materials “flame-resistant”. Depending on the individual product and the safety requirements, more than 200 different types of flame retardants can be used.

Brominated compounds are among the most effective substances that can be used for fire safety solutions. Because bromine is so effective, only a small amount of it is needed to achieve fire resistance. There are more than 70 chemical substances Brominated flame retardants on the market, each with different properties. They are generally referred to as “BFR”. Now let’s discover how bromine works as a fire safety solution!

The effectiveness of bromine as a flame retardant

We already talked about the chemical reaction of fire and about the addition of brominated flame retardants to this process. But which specific effects does bromine have?

There are several ways FR can slow down a fire: by inhibiting the radical reaction in the gas phase (which a fire is, chemically speaking), by forming an isolating layer, by cooling the process (eg, via release of bound water), diluting the fire gases, etc. Brominated substances work by inhibiting the fire in the gas phase. Relatively small amounts of bromine are needed to achieve this

The decomposition of materials in the fire is also limited by physically insulating the available fuel sources from the material source with a fire-resisting char layer.

If a fire does occur, flame retardants slow down the spread of fire by diluting the flammable gasses and oxygen concentrations in the flame formation.

Responding to chemical safety concerns around HBCD

Until recently, HBCD (hexabromocyclodecane) was the main flame retardant used in Extruded Polystyrene foam (XPS) and Expanded Polystyrene foam (EPS) used mainly in insulation for buildings. When HBCD was classified in 2008 as PBT (Persistent, Bioaccumulative and Toxic) and POP (Persistent Organic Pollutant) in 2014, a global replacement was needed.

The global concern accelerated the search for a new brominated flame retardant. The new solution should meet the advanced global fire code requirements in polystyrene foams and have an improved hazard profile compared to HBCD. In addition, the flame retardant should be compatible with the production processes of the polystyrene, i.e. thermally stable for the creation of XPS foam, and provide an emulsion stability for developing EPS foam, while all foam properties and standards have to be maintained. On top of that, there is the economic reality. An acceptable cost and a large commercial availability of resources are a necessity for the replacement to succeed.

High molecular weight brominated polymer: the efficient, non-hazardous sustainable solution

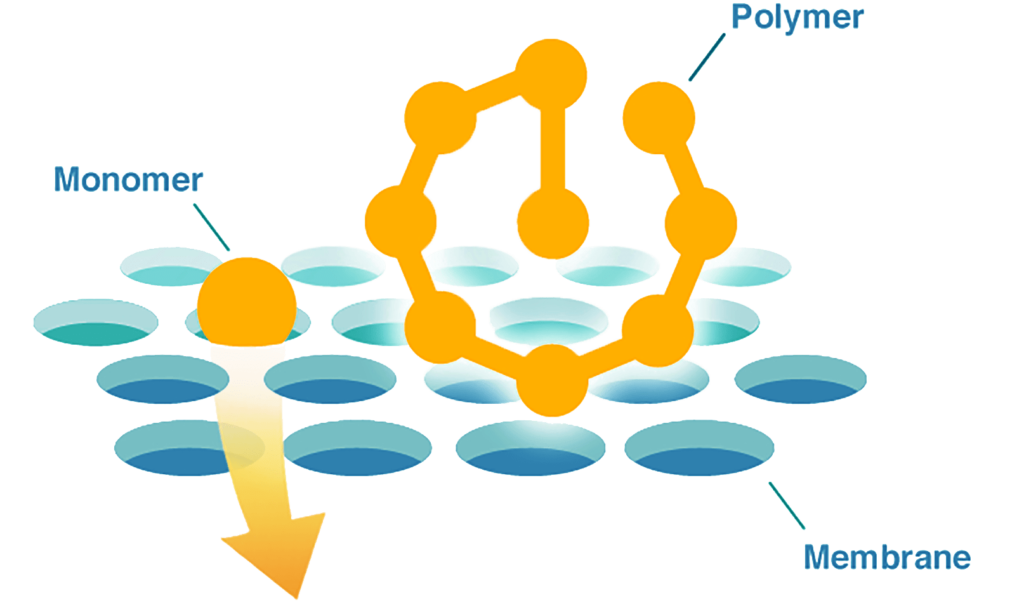

This new polymeric FR is a non-hazardous flame retardant that meets all defined criteria. In addition, it is a high molecular weight polymer. High molecular polymers have a low potential to pass through cell membranes and hence to interact with living organisms. They are therefore less likely to accumulate in an organism and to be absorbed by the body in case of exposure or ingestion.

Such solutions that combine performance and efficiency, while ensuring a good environmental profile point the way to continued use of bromine-based flame retardants.

Brominated flame retardants make up the largest commercial use of bromine. Visit our website to read more about BSEF’s vision on bromine as a flame retardant. Or have a look at our blog on the recently published book “Introduction to flame retardancy – Protect your life and property from fire”, an interesting co-operation between Professor Masaru Kitano and BSEF.

What are your thoughts on the evolutions in flame retardants, and on our growing need of them due to modern life trends?

Do not hesitate to share this article, to give your opinion and to start the conversation.

SOURCES

Polystyrene foam insulation with a sustainable flame retardant: Transforming the market, The Dow Chemical Company

Introduction to flame retardancy – Protect your life and property from fire, Marasu Kitano

https://chemicalwatch.com/16534/end-in-sight-for-flame-retardant-hbcd

http://www.dow.com/en-us/building/industry-updates/canada-styrofoam-flame-retardant-announced

No Comments