17 Oct VECAP: Ensuring the Sustainable Management of Brominated Flame Retardants

VECAP, The Voluntary Emissions Control Action Programme, is a programme developed by BSEF members to demonstrate that the flame retardant industry is doing its share to control the emissions of flame retardants at the production and use stages.

VECAP encourages companies to practice environmentally responsible handling of chemicals, including brominated flame retardants (BFRs).

What is VECAP?

VECAP was devised as a programme to control emissions during the processing and use of brominated flame retardants. Today the programme has evolved into a best practice dissemination scheme run under the principles of Responsible Care®*.

The main goal of the programme is to control and reduce potential emissions of Brominated Flame retardants by tracking, reporting and promoting environmental best practices during the manufacturing and use stages.

It was founded by three of the leading global producers of flame retardants (all members of BSEF, the International Bromine Council) together with the UK Textile Finishers Association.

*Responsible Care®: the global chemical industry’s unique initiative to improve health, environmental performance, enhance security, and to communicate with stakeholders about products and processes.

VECAP reporting method

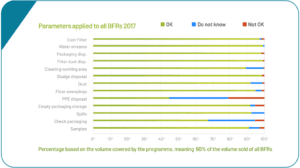

Every year participating users receive a questionnaire to fill in that shows how they have handled relevant brominated flame retardants throughout the year. The survey tool covers every step of the user’s manufacturing process to ensure an accurate understanding of the methods applied at every potential emission point.

Reward system

As an acknowledgement of their efforts and commitment, participants are assigned a gold, silver or bronze status based on their performance with implementing the VECAP best practices.

Constant innovation

VECAP members are committed to increase participation and raise awareness among existing and new users. They also encourage continuous improvement of the programme by developing new best practice recommendations based on experience and evolution in manufacturing processes.

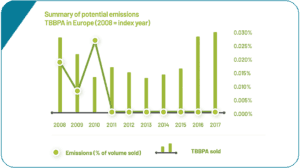

2017 European Progress Report: what has been achieved?

Some numbers

2017 marks the third year of reporting of all solid brominated flame retardants (BFRs). Initially the programme applied to Deca-BDE, TBBPA and HBCD but the application was extended to all powder BFRs when the significant impact of the VECAP programme became clear.

- the results of the European Progress Report show the successful implementation of VECAP best practices across the region

- the volume of BFRs covered by the programme has remained stable (compared to the previous reporting period) covering 90% of total BFRs sold by the founding member companies in 2016

- 71.7% of the total volume of BFRs commonly sold in 2016 was handled using all VECAP best practices and was assigned Gold status

- 11.5% of the total volume sold met the criteria for Silver status

- 6.3% of the volume covered of all BFRs sold was assigned Bronze status

- Over 83% of the all BFRs commonly sold were handled correctly

Would you like to know more about how the VECAP programme works? You can read the full report here: http://www.bsef.com/sustainability/vecap/

Is your company already part of the VECAP programme?

Do not hesitate to share this article, to give your opinion and to start the conversation.

SOURCES

http://bsef.com/sustainability/vecap/

https://www.vecap.info/index.php

https://www.vecap.info/uploads/VECAP_BROCHURE_2016_online.pdf

No Comments